Concerning rockets or launch vehicles, next I would like to write about the following topics:

- ¿What is a rocket?

- Thrust

- The Tsiolkovsky Rocket Equation

- Staging

- Liquid-fuel Rockets

- Liquid-fuel Rocket Engine

- Solid-fuel Roquets

- Orbital and Escape Velocity

- Historic Rockets

- The Future: Space Launch System

¿What is a rocket?

Rockets consist mainly of a propellant, a place to put propellant (such as a propellant tank), a rocket engine and a nozzle. They may also have some directional stabilization devices (such as fins, vernier engines or engine gimbals for thrust vectoring, gyroscopes).

Rockets are accelerated by explosive thrust in the opposite direction. Some kind of fuel is burned with an oxidizer, or propellant, in a combustion chamber, creating hot gases accompanied by high pressure.

Rockets are generally classified as either solid or liquid. They produce thrust by burning propellants and expelling the combustion products out of the engine.

The propellants for rockets are held in tanks or within cases. This is both an advantage and a disadvantage. Because they carry their propellants (oxygen onboard), rockets can work in space. No other presently available vehicle can do that.

A rocket is different from a jet engine. A jet engine cannot function in space because it is an “air-breather.” Although jets and rockets both employ Newton’s law of action and reaction, the jet needs to draw in air from the atmosphere to burn its fuel. This limits the altitude of a jet plane.

A rocket is different from a jet engine. A jet engine cannot function in space because it is an “air-breather.” Although jets and rockets both employ Newton’s law of action and reaction, the jet needs to draw in air from the atmosphere to burn its fuel. This limits the altitude of a jet plane.

Thrust

Whether powered by liquids or solids, rocket systems are propelled by gas pressure resulting from fuel combustion. The force driving them forward is called thrust, which is the forward or upward force produced by the engines of a plane or a rocket.

If the rocket system (the liquid or solid booster plus payload) is to move upward against gravity, the thrust must be greater than gravity’s counteracting downward pull.

The ratio between these two values is called the thrust-to-weight ratio of the booster. At liftoff, the Saturn V thrust-to-weight ratio was 1.2, enough to allow the Eagle to land on the Moon surface.

As propellants burn, the thrust-to-weight ratio increases, and the booster continues to accelerate at higher rates. By exerting more force, or thrust, to a given payload, it will achieve a much higher velocity before thrust termination.

Whether powered by liquids or solids, rocket systems are propelled by gas pressure resulting from fuel combustion. The force driving them forward is called thrust, which is the forward or upward force produced by the engines of a plane or a rocket.

If the rocket system (the liquid or solid booster plus payload) is to move upward against gravity, the thrust must be greater than gravity’s counteracting downward pull.

The ratio between these two values is called the thrust-to-weight ratio of the booster. At liftoff, the Saturn V thrust-to-weight ratio was 1.2, enough to allow the Eagle to land on the Moon surface.

As propellants burn, the thrust-to-weight ratio increases, and the booster continues to accelerate at higher rates. By exerting more force, or thrust, to a given payload, it will achieve a much higher velocity before thrust termination.

A Space Shuttle Main Engine (SSME) undergoing a full power level 290 second test firing at the National Space Technology Laboratories in Mississippi in 1981. The firings were part of a series of developmental testing designed to increase the amount of thrust available to the Shuttle from its three main engines. The additional thrust allowed the Shuttle to launch heavier payloads into orbit

The Tsiolkovsky Rocket Equation

Konstantin Tsiolkovski was a teacher, theorist, and astronautics pioneer. He is considered the father of cosmonautics and human spaceflight. Tsiolkovski advocated liquid propellant rocket engines, orbital space stations, solar energy, and colonization of the Solar System.

The Tsiolkovsky rocket equation, or ideal rocket equation, is based on Newton’s second law of motion and describes the motion of vehicles that follow the basic principle of a rocket: a device that can apply acceleration to itself (a thrust) by expelling part of its mass with high speed and thereby move due to the conservation of momentum.

The equation relates the Δv (the maximum change of velocity of the rocket if no other external forces act) with the effective exhaust velocity ve and the initial and final mass of the rocket.

The equation relates the Δv (the maximum change of velocity of the rocket if no other external forces act) with the effective exhaust velocity ve and the initial and final mass of the rocket.

Tsiolkovsky rocket equation

where:

- Δv: is the maximum change of velocity of the vehicle (with no external forces acting).

- m0: is the initial total mass, including propellant.

- mf: is the final total mass without propellant, also known as dry mass.

- ve: is the effective exhaust velocity.

- ln: refers to the natural logarithm function.

Analyzing his equation, obtained in 1898 and published in 1903, Tsiolkovsky came to another inportant conclusion as well as demonstrating that space travel was possible. It would be impossible for a single-stage rocket to carry humans into the outer space powered by fuel because the weight of the fuel would far outweigh the weight of the whole rocket.

So he analyzed the way a multi-stage rocket would make the trip possible. A multi-stage or stage rocket actually consists of several assembled rockets. When the first one has burned all its fuel, the next phase is released and ignites.

Staging

To achieve the greater and greater velocities required to send a given mass farther and farther out into space, higher thrust must be exerted or it must be applied for a longer period of time.

Concerning rockets, mass does not remain the same; it decreases. As each kilogram of propellant is burned, the mass of the ascending vehicle becomes one kilogram less, and large rocket engines may burn hundreds of tons of propellant in seconds.

As a result, the same thrust has much less mass to accelerate. The decrease in weight allows an increase in acceleration. This principle is used in the concept of “staging”.

Apollo 6 while dropping the interstage ring

A space launch vehicle usually consists of a number of sections known as stages. After the first rocket stage accelerates the entire vehicle and finally burns out, its tanks and motors are discarded because they are no longer needed and add unnecessary weight that slows acceleration.

The same happens in the second and subsequent stages. The payload is finally all that remains, having been accelerated to the necessary velocity.

Liquid- and solid-fuel rockets

Liquid- and solid-fuel rockets each have special capabilities, advantages, and applications. Liquid rockets are often preferred for space missions because of their more efficient use of propellants. For example, the Russian Soyuz uses liquid fuels.

Because of their high thrust and simplicity, however, solid-fuel rockets are also used with space launch vehicles. Some launch vehicles, such as the space shuttle, combine both liquid engines and solid motors.

Propellants are simply a combination of fuel and oxidizer. The oxidizer for solid propellants is a chemical containing oxygen. For example, gunpowder, used in the engines of model rockets, contains potassium nitrate (KNO3). Potassium nitrate provides the oxygen needed for the other gunpowder chemicals to burn rapidly.

On the other hand, the oxidizer for liquid rockets is usually pure oxygen chilled to 90 K (-183°C) so that it condenses into liquid oxygen.

On the other hand, the oxidizer for liquid rockets is usually pure oxygen chilled to 90 K (-183°C) so that it condenses into liquid oxygen.

Liquid Propellant Rockets

Liquid propellant rockets are an invention of the twentieth century. They are far more complex than solid rockets. Generally, a liquid rocket has two large tanks within its body. One tank contains a fuel, such as kerosene or liquid hydrogen while the other tank contains liquid oxygen.

Liquid Propellant Rockets Engines

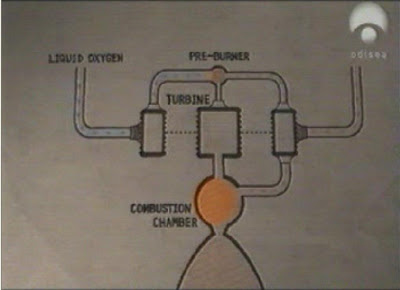

When the liquid rocket engine is fired, high-speed pumps force the propellants into a cylindrical or spherical combustion chamber.

The fuel and oxidizer mix as they are sprayed into the chamber. There they ignite and expand, pushing equally in every direction. A relatively small hole, called the throat, exists at the bottom of the chamber and leads to an exhaust nozzle.

The expanding gases pushing in all directions inside the chamber push through the throat and out against the widening sides of the nozzle. As a given volume of gas reaches the edge of the nozzle, it spreads out over a much greater area than at the throat, so that the pressure on the edge of the nozzle is less than the pressure within the combustion chamber.

Liquid propellant engines have a number of advantages over solid propellant engines. A wider array of propellant combinations are available for different applications. Some of these require an ignition system and others simply ignite on contact.

Liquid Propellant Rocket

Liquid Propellant Rockets Engines

When the liquid rocket engine is fired, high-speed pumps force the propellants into a cylindrical or spherical combustion chamber.

The fuel and oxidizer mix as they are sprayed into the chamber. There they ignite and expand, pushing equally in every direction. A relatively small hole, called the throat, exists at the bottom of the chamber and leads to an exhaust nozzle.

The expanding gases pushing in all directions inside the chamber push through the throat and out against the widening sides of the nozzle. As a given volume of gas reaches the edge of the nozzle, it spreads out over a much greater area than at the throat, so that the pressure on the edge of the nozzle is less than the pressure within the combustion chamber.

The sum of all the pressures inside the chamber acting on the chamber and nozzle skirt in a forward or upward direction is more than the sum of all the pressures acting in a rearward or downward direction. This net difference makes the rocket engine and the vehicle attached to it lift from the launch pad.

Rocket engines give part of their thrust due to unopposed pressure on the combustion chamber (Image created by Hartmut Redlefs)

Liquid propellant engines have a number of advantages over solid propellant engines. A wider array of propellant combinations are available for different applications. Some of these require an ignition system and others simply ignite on contact.

Monomylmethylhydrozene (fuel) and nitrogen tetroxide (oxidizer) ignite spontaneously. These are called hypergolic propellants. With hypergolic propellants, a rocket engine does not need an ignition system. Another advantage of liquid propellants is that they can be controlled.

Adjusting their flow into the combustion chamber adjusts the amount of thrust produced. Furthermore, liquid engines can be stopped and restarted later. It is very difficult to stop a solid propellant rocket once it is started, and thrust control is limited.

Adjusting their flow into the combustion chamber adjusts the amount of thrust produced. Furthermore, liquid engines can be stopped and restarted later. It is very difficult to stop a solid propellant rocket once it is started, and thrust control is limited.

Of course, as with any technology, there is a price to pay. The engine of a liquid propellant rocket is very complex and subject to failure. It also has more structural mass than comparable solid propellant rockets.

Solid Propellant Rockets

Another kind of rocket has come into wide use as part of military weapon systems and spaceflight boosters. This is the solid-propellant rocket. The space shuttle and other space boosters use both solid- and liquid-fueled rockets as a part of their “stack”.

The SRBs (Solid Rocket Booster) have many other sophisticated innovations, but, in principle, they are no different from their primitive ancestors. Solid propellant rockets have a simple design. They consist of a case or tube in which the propellants are packed.

It was discovered that mixing a chemical oxidizer and fuel, often aluminum powder, with a polymer (polymers are the basis of synthetic rubber and plastics and include substances like nylon) to provide the needed oxygen with the polymer resulted in a substance with a consistency similar to peanut butter.

This substance could be poured into forms and baked into a rubbery solid material that burned furiously when ignited and created large volumes of gases, producing a great thrust.

The perforation, a carefully designed hole through the propellant, is formed when the fuel is cast to fit into the rocket’s cavity. Varying the size and shape of the perforation determines the rate and duration of combustion, which controls the thrust.

It was discovered that mixing a chemical oxidizer and fuel, often aluminum powder, with a polymer (polymers are the basis of synthetic rubber and plastics and include substances like nylon) to provide the needed oxygen with the polymer resulted in a substance with a consistency similar to peanut butter.

This substance could be poured into forms and baked into a rubbery solid material that burned furiously when ignited and created large volumes of gases, producing a great thrust.

The perforation, a carefully designed hole through the propellant, is formed when the fuel is cast to fit into the rocket’s cavity. Varying the size and shape of the perforation determines the rate and duration of combustion, which controls the thrust.

This image illustrates the solid rocket motor (SRM)/solid rocket booster (SRB) configuration. The Shuttle's two SRB's are the largest solids ever built and the first designed for refurbishment and reuse. Standing nearly 150-feet high, the twin boosters provide the majority of thrust for the first two minutes of flight, about 5.8 million pounds, augmenting the Shuttle's main propulsion system during liftoff

Early rockets used cases made of paper, leather, and iron. Modern rockets use a thin and lightweight metal such as aluminum. Making the case from thin metal reduces the overall weight of the structure and increases flight performance. However, the heat from the burning propellants could easily melt through the metal. To prevent this, the inner walls of the case have to be insulated.

The upper end of the rocket is closed off and capped with a payload section or recovery parachutes. The lower end of the rocket is constricted with a narrow opening called the throat, above a larger cone shaped structure, called the nozzle. By constricting the opening, the throat causes the combustion products to accelerate greatly as they race to the outside (second law). The nozzle aims the exhaust straight downward so that the rocket travels straight upward.

The propellant in solid rockets is packed inside the insulated case. It can be packed as a solid mass or it may have a hollow core. When packed as a solid mass, the propellant burns from the lower end to the upper end.

Depending upon the size of the rocket, this could take a while. With a hollow core, the propellants burn much more rapidly because the entire face of the core is ignited at one time. Rather than burning from one end to the other, the propellant burns from the core outward, towards the case.

The upper end of the rocket is closed off and capped with a payload section or recovery parachutes. The lower end of the rocket is constricted with a narrow opening called the throat, above a larger cone shaped structure, called the nozzle. By constricting the opening, the throat causes the combustion products to accelerate greatly as they race to the outside (second law). The nozzle aims the exhaust straight downward so that the rocket travels straight upward.

The propellant in solid rockets is packed inside the insulated case. It can be packed as a solid mass or it may have a hollow core. When packed as a solid mass, the propellant burns from the lower end to the upper end.

Depending upon the size of the rocket, this could take a while. With a hollow core, the propellants burn much more rapidly because the entire face of the core is ignited at one time. Rather than burning from one end to the other, the propellant burns from the core outward, towards the case.

The advantage of a hollow core is that the propellant mass burns faster, increasing thrust. To make solid rockets even more powerful, the core doesn’t have to be round. It can have other shapes that increase the surface area available for burning.

The upper ends of the space shuttle SRBs had star-shaped cores. When ignited, the large surface area of the star points boosted liftoff thrust. In about one minute, however, the points burned off, and the thrust diminished somewhat. This was done on purpose because the space shuttle begins accelerating through the sound barrier. Passing through causes vibrations that are diminished by the temporary thrust reduction of the SRBs.

Orbital Velocity

Velocity is a critical factor. The velocities needed for specific space missions were calculated long before spaceflight was possible. To put an object into orbit around Earth, for instance, a velocity of at least 8 kilometers per second (18,000 miles per hour) must be achieved, depending on the precise orbit desired. This is called orbital velocity.

Orbital velocity is attained when the vehicle is moving in the right direction, fast enough to miss Earth as it falls back. The actual resulting course keeps it in space. In effect, it is falling continually around Earth.

Escape Velocity

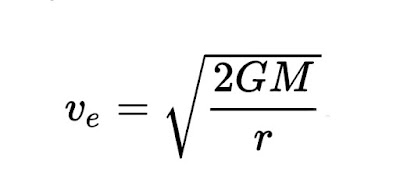

To break away from Earth’s gravity for distant space missions, a velocity greater than 11 kilometers per second (25,000 miles per hour) is required. This is called escape velocity.

Escape Velocity

Historic Rockets

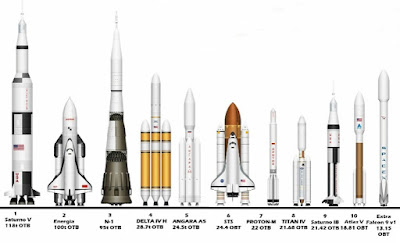

Some of the rockets more importants in history

V2

The largest military research project of the Third Reich was the development of a rocket at Peenemünde. They called it Aggregat 4, but it was known under the name V2 (Vergeltungswaffe 2). With the A4, researchers created the building blocks for liquid-fuel ballistic missiles.

V2 rocket designed by Von Braun during the Second World War

In the nose cone was the explosive material, behind it lay the control system and two fuel tanks. The propulsion system with the thrust nozzle formed the tail of the rocket.

In 2006, while I was in Berlin, I visited the German Museum of Technology (Deutsches Technikmuseum) where I can learn a lot about the V2 rocket. Next you can see some pictures I took there.

Combustion chamber of a V2 rocket

Fuel tank of a V2 rocket

Diagram with the main components of a V2 rocket

Turbopump of a V2 rocket located between the tank and the combustion chamber

Nozzle of a V2 rocket

The engines of the A4 burned about 60 seconds pure liquid oxygen with a mixture of 75% ethyl alcohol and 25% water. A specially developed turbopump fed the alcohol mixture and the liquid oxygen at a temperature of 183 degrees below zero into the combustion chamber, where an explosive reaction took place. This combustion accelerated the rocket to about five times the sound velocity.

Russian Rockets

Soyuz TM-31 launcher

Russian Rockets

This shows the evolution of Soviet space launch vehicles in the early years. From the left are the R-7 ICBM (Intercontinental Ballistic Missile), the Sputnik launcher, the Vostok launcher, and the Soyuz launcher. Image under copyright by Peter Gorin. Image and caption from Challenge to Apollo: The Soviet Union and the Space Race, 1945- 1974 (NASA SP-2000-4408) by Asif A. Siddiqi

Soyuz TM-31 launcher

Soyuz TM-31 launcher about to liftoff in Baikonur in 1975

Proton

Proton is an expendable launch system used for both commercial and Russian government space launches. The first Proton rocket was launched in 1965. Modern versions of the launch system are still in use as of 2016, making it one of the most successful heavy boosters in the history of spaceflight.

With a thrust of 2,500,000 pounds-force, Proton launched the unmanned Soviet circumlunar flights, the Salyut space stations, the Mir core segment and expansion modules, and both the Zarya and Zvezda modules of the ISS.

Saturn V

The Saturn V is the largest and most powerful launch vehicle in the United States. The towering, 111 meter, Saturn V was a multistage, multiengine launch vehicle standing taller than the Statue of Liberty. This impressive rocket generated 33 million newton (7.5 million pounds-force) of thrust at liftoff.

Diagram of the Saturn V launch vehicle showing the three stages, the instrument unit, and the Apollo spacecraft. The chart on the right presents the basic technical data in clear metric detail

Saturn V rocket used in Apollo XI mission which made possible for the first time a moon walk

Space Shuttle

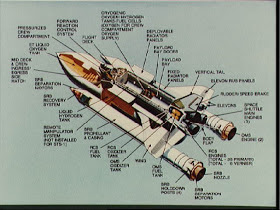

The space shuttle was a new concept for carrying crews and payloads into low Earth orbit. It consisted of a central external tank surrounded by two solid rocket boosters and a winged orbiter achieving about 28 million newton (6.25 million pounds-forcey) of thrust. Only the orbiter, a spacecraft, actually reached orbit.

It was designed to be reusable as were the solid rocket boosters. A new external tank was needed for each mission. Inside a cavernous payload bay were science laboratories, space probes, telescopes, or Earth-sensing systems.

Many shuttle payloads consisted of components for the International Space Station. At the end of a shuttle mission, the orbiter reentered Earth’s atmosphere and glided to an unpowered landing on a runway. The first space shuttle flight took place in 1981 and the last of its 135 missions concluded in 2011.

It was designed to be reusable as were the solid rocket boosters. A new external tank was needed for each mission. Inside a cavernous payload bay were science laboratories, space probes, telescopes, or Earth-sensing systems.

Many shuttle payloads consisted of components for the International Space Station. At the end of a shuttle mission, the orbiter reentered Earth’s atmosphere and glided to an unpowered landing on a runway. The first space shuttle flight took place in 1981 and the last of its 135 missions concluded in 2011.

The major design drivers for the SRM's of the Space Shuttle were high thrust and reuse. The desired thrust was achieved by using state-of-the-art solid propellant and by using a long cylindrical motor with a specific core design that allows the propellant to burn in a carefully controlled marner. At burnout, the boosters separate from the external tank and drop by parachute to the ocean for recovery and subsequent refurbishment.

Main components of a Space Shuttle vehicle

The solid rocket boosters (SRBs) for the space shuttle are very large tubes packed with propellants that are closed off at one end and have a hole at the other. The boosters are designed to survive water impact at almost 60 miles per hour, maintain flotation with minimal damage.

Ariane V

Ariane V is an European heavy lift launch vehicle that is part of the Ariane rocket family, an expendable launch system used to deliver payloads into geostationary transfer orbit (GTO) or low Earth orbit (LEO).

The Ariane 5 launcher consists of the Main Cryogenic Stage, two Solid Boosters and an Upper Stage. Using a limited number of engines, this architecture is both simple and robust.

Ariane V’s cryogenic consists of a large tank 30.5 metres high with two compartments, one for liquid oxygen and one for liquid hydrogen, and a Vulcain 2 engine at the base with a vacuum thrust of 1,390 kilonewtons (310,000 pounds-force). It weighs about 189 tonnes, including 175 tonnes of propellant.

Attached to the sides are two solid rocket boosters (SRBs or EAPs from the French Étages d’Accélération à Poudre), each weighing about 277 tonnes full and delivering a thrust of about 7,080 kilonewtons (1,590,000 pounds-force). They are fueled by a mix of ammonium perchlorate (68%) and aluminum fuel (18%) and polybutadiene (14%). They each burn for 130 seconds before being dropped into the ocean.

So the thrust of an Ariane 5 is about 3,500,000 pounds-force) being able to carry payloads weighing more than 10 metric tons to geostationary transfer orbit (GTO) and over 20 metric tons into low-Earth orbit (LEO).

Ariane V rocket in La Cité de l'Espace (Space City) in Toulouse

Nozzle of the Vulcain engine of Ariane V rocket in Le Parc de la Villette in Paris

Some of the most important payloads Ariane V has delivered are the probes Rosetta, Planck and Herschel, Galileo constellation Satellites, and the ATV (Automatic Transfer Vehicle).

Titan IV

The Titan IV heavy lift space launch vehicle looks like three rockets joined together side by side.

The launch vehicle, Cassini spacecraft and attached Centaur stage encased in a payload fairing, altogether stand about 183 feet tall; mounted at the base of the launch vehicle are two upgraded solid rocket motors

On the outside are huge solid-fuel motors with a combined thrust of more than 3 million pounds-force. When these burn out, they fall away from the central core, which then continues the mission.

Titan IV launcher compared with other rockets. N-1 was an unsuccesful russian rocket, Energia together with the Buran orbiter had not continuity because of the collapse of the Soviet Union and Angara is a russian launcher currently in devolpment

The middle part is itself a two- or three-stage vehicle, but liquid-fueled. In addition to mass, other factors affect velocities necessary for space operations.

The higher a rocket goes from Earth, the thinner the atmosphere becomes, decreasing the amount of friction or drag imparted on the rocket. In space there is very little if any atmosphere and essentially no friction or drag. The pull of gravity becomes less the farther you move away from Earth’s center. This effect is not significant for satellites orbiting a few hundred miles above Earth, but it becomes important if the spacecraft is to be sent thousands of miles into space. Packaging the energy of a rocket vehicle into stages that can be discarded as they burn out has been the secret of launching into space. The number of stages may vary from two to five or even more.

Atlas V

The Atlas V family are the latest evolutionary versions of the Atlas launch system. Atlas V uses a standard common core booster (CCB), up to five solid rocket boosters (SRB), an upper-stage Centaur in either the Single-Engine Centaur (SEC) or the Dual-Engine Centaur (DEC) configuration, and one of several payload fairings.

The main engine of Atlas V launch system delivers more than 860,000 pounds-force of thrust at liftoff using liquid Oxygen and liquid Kerosene as an Oxidizer and fuel.

When missions demand additional thrust at liftoff, Atlas integrates up to five Solid Rocket Boosters on the Atlas V 500 series vehicles with a thrust of 380,000 pounds-force (total thrust of 1,900,000 pounds-force)

Some notable payloads derivered by Atlas V are:

- Mars Reconnaissance Orbiter

- New Horizons

- LRO/LCROSS

- Solar Dynamics Observatory

- Boeing X-37B

- Juno

- Mars Science Laboratory

- OSIRIS-REx

- Curiosity

Delta IV Heavy

The Delta IV Heavy is an expendable heavy lift launch vehicle, the largest type of the Delta IV family. It is manufactured by United Launch Alliance and it was first launched in 2004.

Delta IV Heavy employing two additional CBCs as liquid rocket boosters achieving a thrust of 2,100,000 pounds-force at liftoff

The Delta IV Heavy employs two additional Common Booster Cores (CBCs) as liquid rocket boosters (LRBs) to augment the first-stage CBC, each one with a thrust of 702,000 pounds-force.

The main engine of Delta IV heavy delivers more than 702,000 pounds-force of thrust at liftoff using liquid Oxygen and liquid Hydrogen as an Oxidizer and fuel.

The Space Launch System

A new and different kind of rocket is needed as NASA prepares to extend its mission beyond low-Earth orbit and out into the solar system.

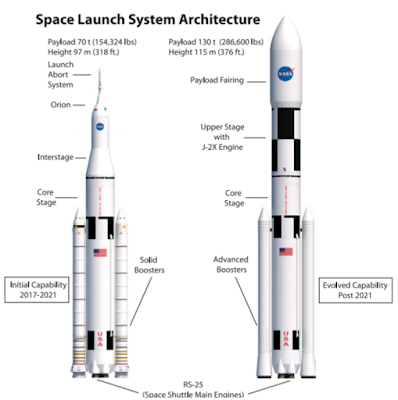

Space Launch System architecture

The Space Launch System (SLS) will be used for Earth orbital flights and long-range missions to places like asteroids or Mars and its moons. The SLS rocket will be the most powerful launch vehicle in history and it is being developed in two phases:

- Heritage hardware (components from previous rockets) is being used to build a heavy-lift rocket for development testing from 2017 to 2021. It will lift up to 70 metric tons of payload. This rocket will make two lunar flybys carrying an Orion spacecraft, the second with a crew.

- The advanced SLS rocket will lift up to 130 metric tons including equipment, cargo, scientific experiments, and/or the Orion spacecraft into deep space.

The SLS rocket is modular so that it can be configured in different ways for different missions. NASA is now planning two configurations, each stacked around a common SLS core stage equipped with RS-25 engines and flanked on either side with either solid or liquid rocket boosters.

These configurations share many other elements and subsystems, as well – such as engines that use liquid oxygen and liquid hydrogen as fuel – so that each costs less to design, build, and launch, without sacrificing the performance required to get the job done. What will they do?

These configurations share many other elements and subsystems, as well – such as engines that use liquid oxygen and liquid hydrogen as fuel – so that each costs less to design, build, and launch, without sacrificing the performance required to get the job done. What will they do?

• One configuration is designed to carry people. Its stack is crowned with the Orion spacecraft, which is larger than the Apollo capsule but otherwise looks similar to it. This configuration also has a rocket tower on top, designed to help the crew escape in case of emergency.

• The other configuration is designed to carry massive amounts of cargo, such as structures,

equipment, scientific experiments, and supplies. Its stack includes a fairing enclosure that is placed over the rocket’s nose to protect the payload.

No hay comentarios:

Publicar un comentario